- Mobile: +86-13962238789

- whatsapp: 008613962238789

- wechat: 008613962238789

- E-mail: [email protected]

|

Brief Introducing: |

|

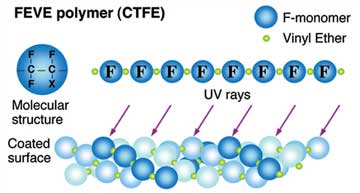

FEVE aluminum composite panel has high quality polyurethane as the primary coat and fluororesin after mid-high baking as the surface coating. It has a good weather resistance up to 10-15 years and is distinguished from the PVDF fluorocarbon coating by features of brilliant color and high gloss, the diversification and uniqueness of which makes it unparalleled by other painting systems. It’s especially applicable in decorations and exhibitions for commercial chains, auto 4S stores, and gas stations where the color effects are required. What Are Fluoroethylene Vinyl Ether (FEVE) Resins? |

|

|

Fluoroethylene Segment Vinyl Ether Segments Weatherability, durability, R1=Clarity, gloss, hardness chemical resistance R2=Flexibility R3=Crosslinking site (-OH) Solubility |

|

PRODUCTS INFORMATION |

|

|

PRODUCTS NAME: |

ALUWEDO® Aluminum Composite Panel |

|

SURFACE COATING: |

FEVE (EVE ) |

|

COLOR RANGE: |

RAL Colors, Panton Colors or Customized Colors |

|

PAINT FINISH: |

Reach to 85% Gloss Level |

|

SIZE AVALAIBLE: |

|

|

Panel Thickness: (mm) |

2mm------ 6mm |

|

Aluminum sheet thickness: (mm) |

0.21mm-----0.5mm |

|

Panel Width: (mm) |

1000mm-----2012mm |

|

Panel Length: (mm) |

Cut any as required |

|

DIMENSIONAL TOLERANCES: |

|

|

Thickness(mm) |

± 0.2mm |

|

Width(mm) |

± 2mm |

|

Length(mm) |

± 3mm |

|

Diagonal(mm) |

± 5mm |

|

Themal Expansion |

2.4mm/m @100 oC Temp Difference |

|

Aluminium Thickness(mm) |

± 0.02mm |

|

SURFACE PROPERTIES: |

|

|

Pencil Hardness |

> HB/> 2H |

|

Temperature Resistance |

-50 oC to +80 oC |

|

Impact strength(kg. cm) |

50 |

|

Boiling Resistance |

Boiling for 2 hours without change |

|

Acid Resistance |

Immerse Surface in 2% HC1 for 48 hours without change |

|

Alkali Resistance |

Immerse Surface in 2% NaOH for 48 hours without change |

|

Oil Resistance |

Immerse Surface in 20# engine oil for 48 hours without change |

|

Solvent Resistance |

Cleaned 100 times with Dimethylbezene without change |

|

PRODUCT PROPERTIES: |

|

|

Sound Absorption NRC |

0.05 |

|

Sound Attenuation Rw db |

23/24/25 |

|

Water Absorption % by volume |

0.0047/0.0057/0.0012 |

|

Core Composition |

LDPE Polyethylene, Non- Combustible Material |

|

FEATURES AND BENEFIT OF FEVE (EVE) |

|

|

ALUWEDO® FEVE (EVE) Aluminum Composite Panel can be directly applied for silk screen, digital printing, spray-print, and instant stick. Meanwhile, it is easy to be cut, punched. It had great feasibility on processing, easy to be fixed to all cladding, including all shapes, angles, curves, radius, bending, joint, connection, etc. It can be finished by normal machines for metal and wood |

|

|

Feature |

Benefit |

|

Fluoropolymer segments |

Outstanding weatherability, corrosion and chemical resistance, lower life cycle costs. |

|

Amorphous and solvent soluble |

Clear, wide range of gloss and color. |

|

Hydroxy functional |

Cure at ambient and elevated temperatures |

|

High solids/solid resins |

Low VOC/reduced VOC coatings |

|

WEATHERING OF FEVE COATING |

|

|

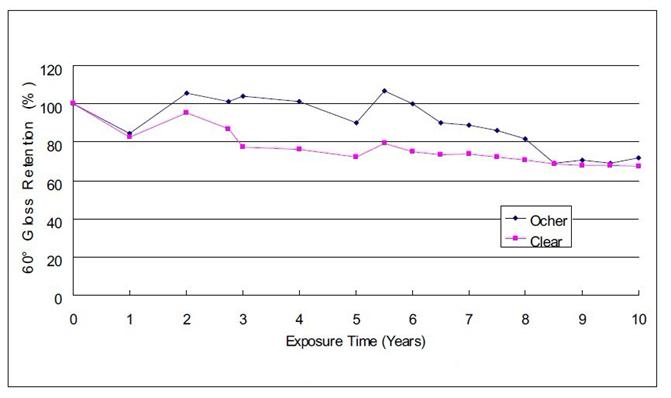

Exposure Test on LF-200 |

|

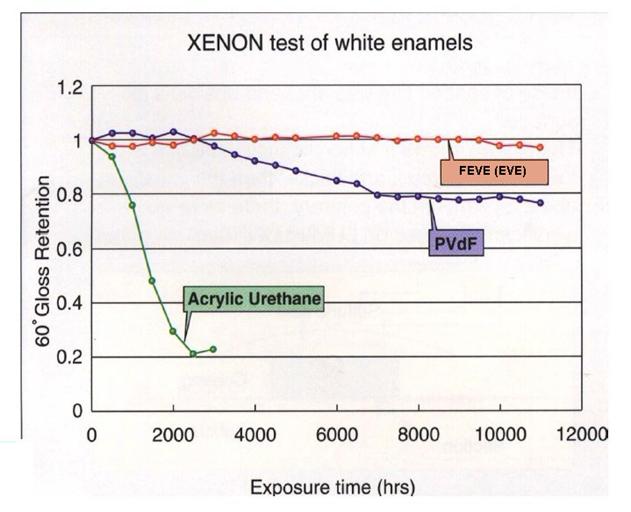

XENON ARC TEST RESULTS OF FEVE COATING |

|

|

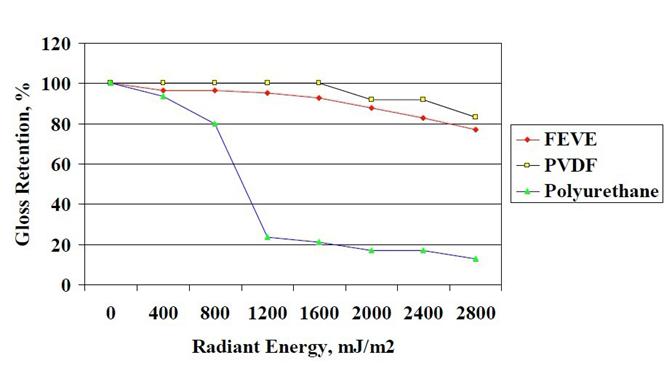

EMMAQUA TESTING OF FEVE COATING |

|

|

UV: Mj/m2 (295-385nm) |

|

|

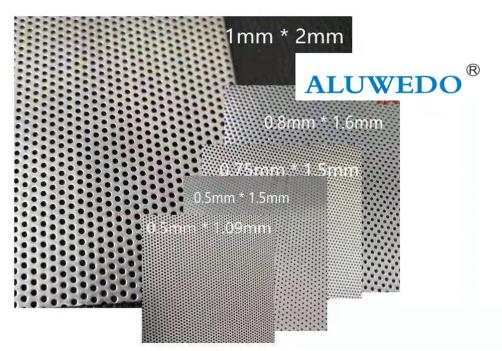

Let’s see it in a little more detail

Punching and die-cutting

The composite panel can be punched and die-cut with CNC. The result ranges from the creation of pointillist or artistic style patterns to complicated and detailed drawings on the facade

Edging

There are three types of edging:

· Simple, which hides the edging

· Double interior, hides the edge and part of the back

· Double outside, hides the edge and extends a flange that hides the joints with other panel sheets.

Roller bending

The panel can be easily bent following the minimum necessary bending radii. To do it, it is best to use bending machines with 3/4 rolls.

By bending the product, columns can be covered, concealing the corners with a rounded appearance, etc.

Stamping and engraving

With more limitations than the previous transformations, we find that in the panel, through modifications in its depth, it is possible to make engravings creating forms without having to get to cut-die the panel.

3D Forming

The 3D forming process, besides of being used to manufacturing aluminium composite panel for hanging systems, can also be used to create projected three-dimensional surfaces

Milling

The milling of the panel gives results that differ from other types of processing such as punching and, of course, from the usual conception of the composite panel as a cassette-type tray. It can be made with CNC, with a wall saw or a portable one. The partial milling of the panel allows the subsequent folding of the pieces to give them creative shapes.