- Mobile: +86-13962238789

- whatsapp: 008613962238789

- wechat: 008613962238789

- E-mail: [email protected]

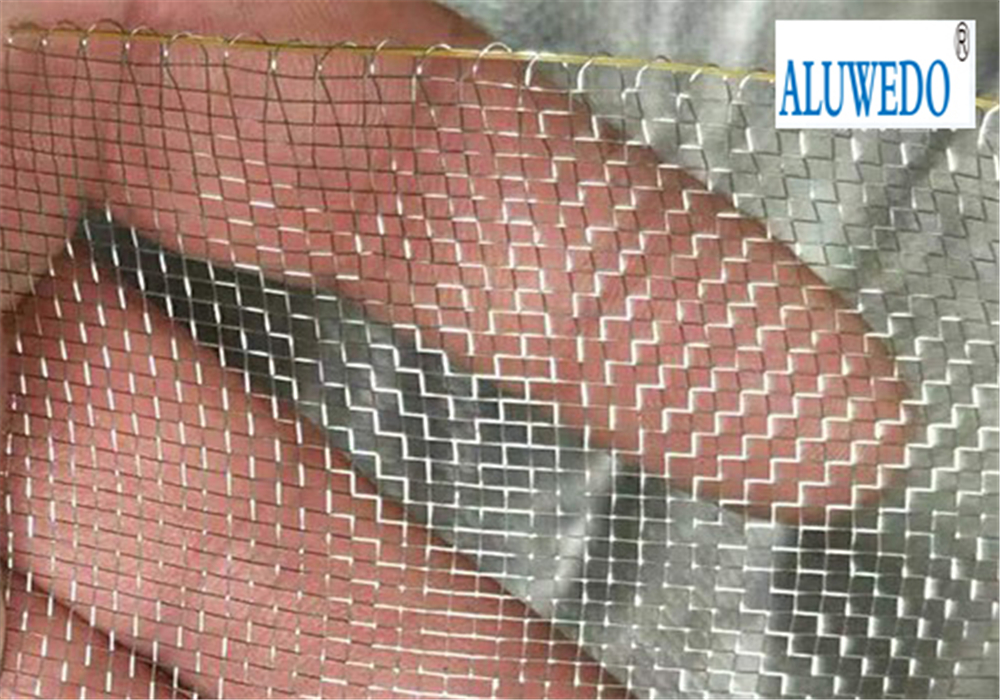

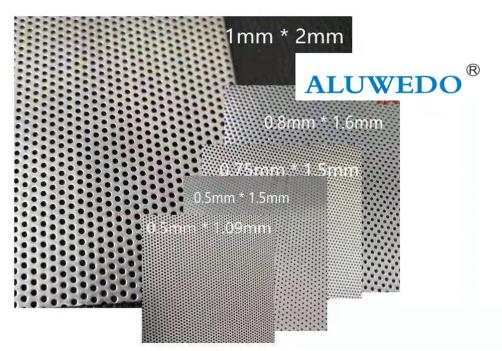

Stainless steel gauze specification: 0.6m-6m wide and 1 mesh-600 mesh.

Features of stainless steel gauze: This product is woven with a plain weave process and has good air permeability and light transmittance. It is currently a substitute for ordinary nylon window screens in China. This product is of high grade and versatile. It is currently used in high-end office buildings, residential buildings and various The preferred protective product for doors and windows in buildings, livestock farms, orchards.

A: Anti-rodent: High strength and toughness, which can avoid a series of hygiene problems caused by rats entering the house.

B: Prevent mosquitoes and flies: In addition to the basic purpose of preventing ordinary mosquitoes and insects, it can also prevent a small wheat and wheat mosquito in humid places.

C: Fire protection: high temperature resistance and flame retardant. Now buildings have fire protection facilities. However, ordinary nylon screens cannot be fireproof, and stainless steel screens can meet the basic fire prevention requirements.

D: Breathable and light-permeable: The surface of this product is bright and beautiful. Compared with ordinary nylon window screens, it can better increase air circulation and sunlight.

Let’s see it in a little more detail

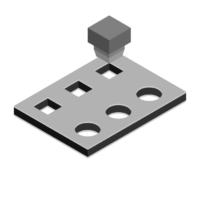

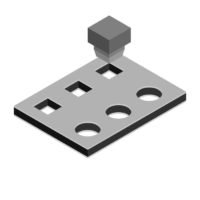

Punching and die-cutting

The composite panel can be punched and die-cut with CNC. The result ranges from the creation of pointillist or artistic style patterns to complicated and detailed drawings on the facade.

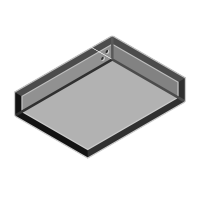

Edging

There are three types of edging:

· Simple, which hides the edging

· Double interior, hides the edge and part of the back

· Double outside, hides the edge and extends a flange that hides the joints with other panel sheets.

Roller bending

The panel can be easily bent following the minimum necessary bending radii. To do it, it is best to use bending machines with 3/4 rolls.

By bending the product, columns can be covered, concealing the corners with a rounded appearance, etc.

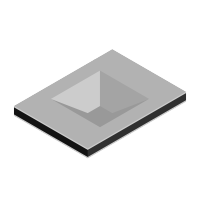

Stamping and engraving

With more limitations than the previous transformations, we find that in the panel, through modifications in its depth, it is possible to make engravings creating forms without having to get to cut-die the panel.

3D Forming

The 3D forming process, besides of being used to manufacturing aluminium composite panel for hanging systems, can also be used to create projected three-dimensional surfaces.

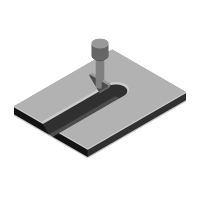

Milling

The milling of the panel gives results that differ from other types of processing such as punching and, of course, from the usual conception of the composite panel as a cassette-type tray. It can be made with CNC, with a wall saw or a portable one. The partial milling of the panel allows the subsequent folding of the pieces to give them creative shapes.