- Mobile: +86-13962238789

- whatsapp: 008613962238789

- wechat: 008613962238789

- E-mail: [email protected]

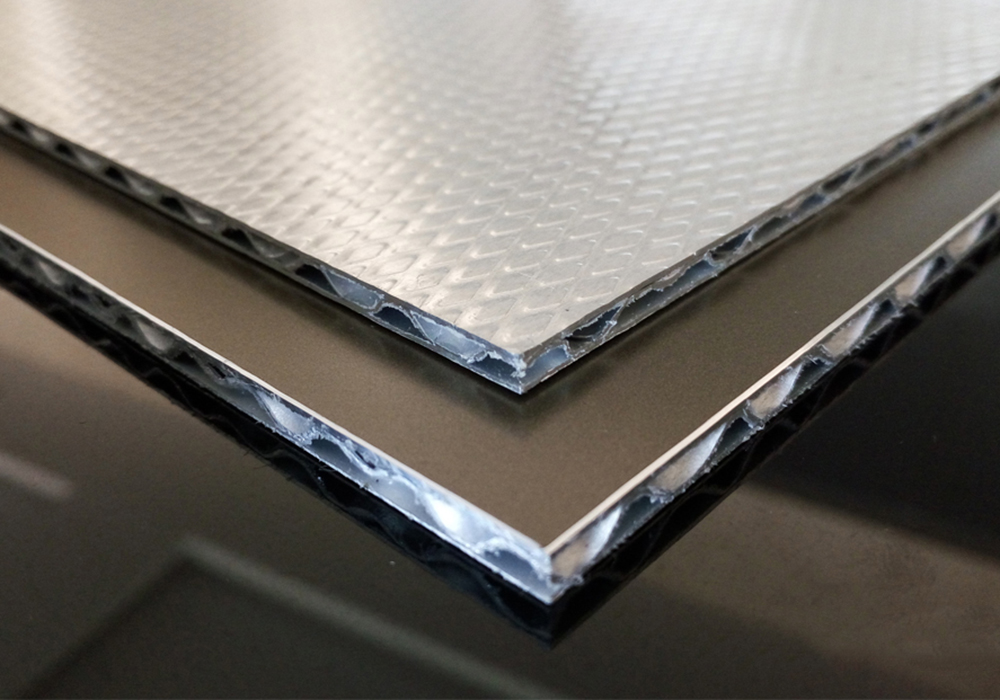

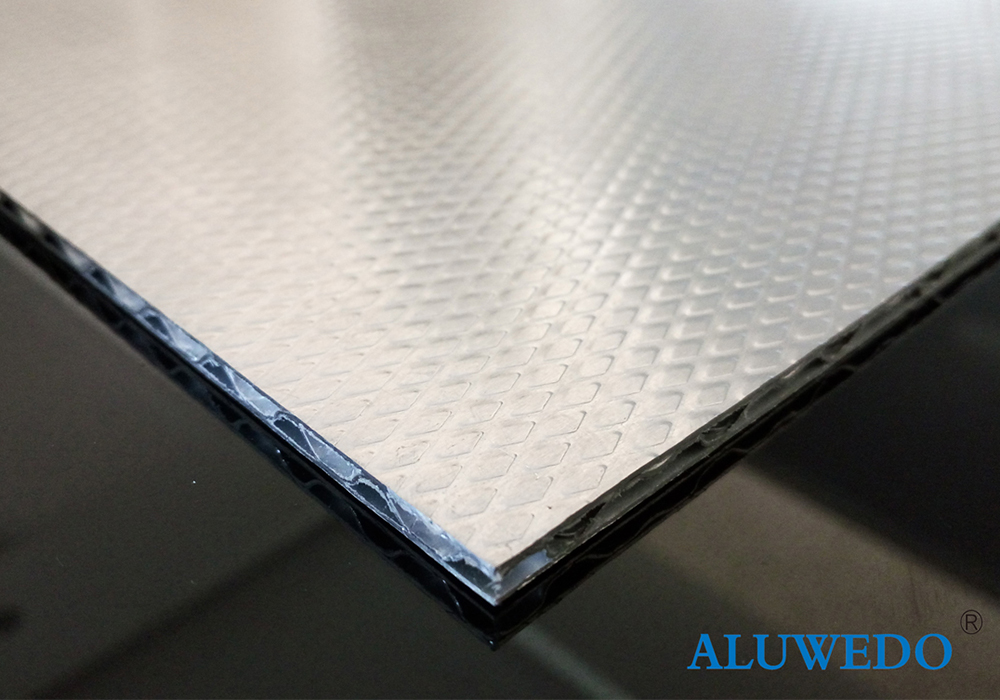

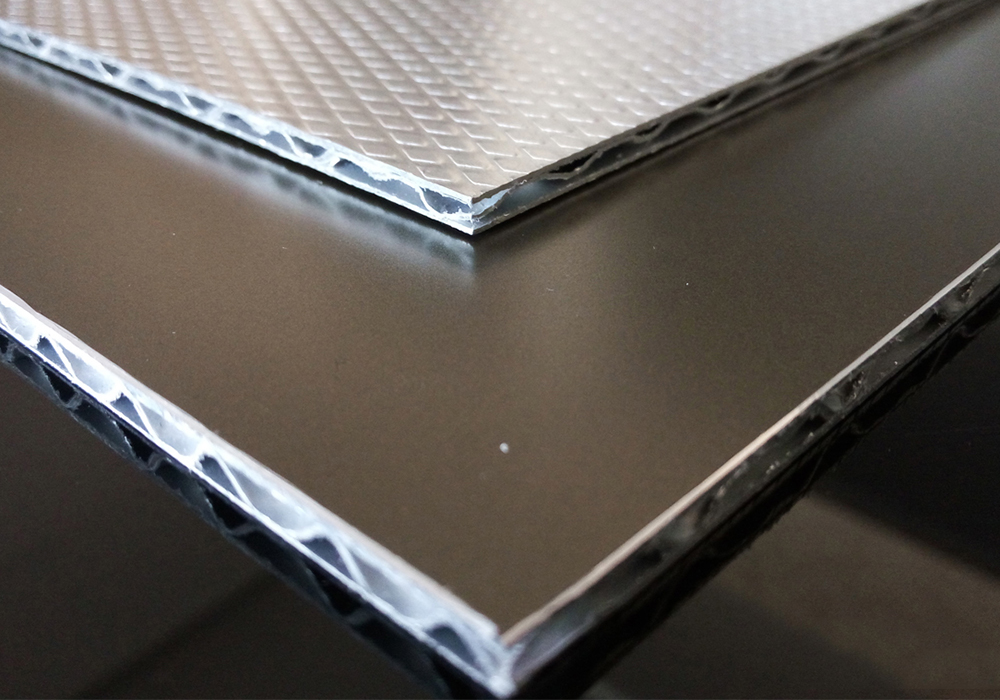

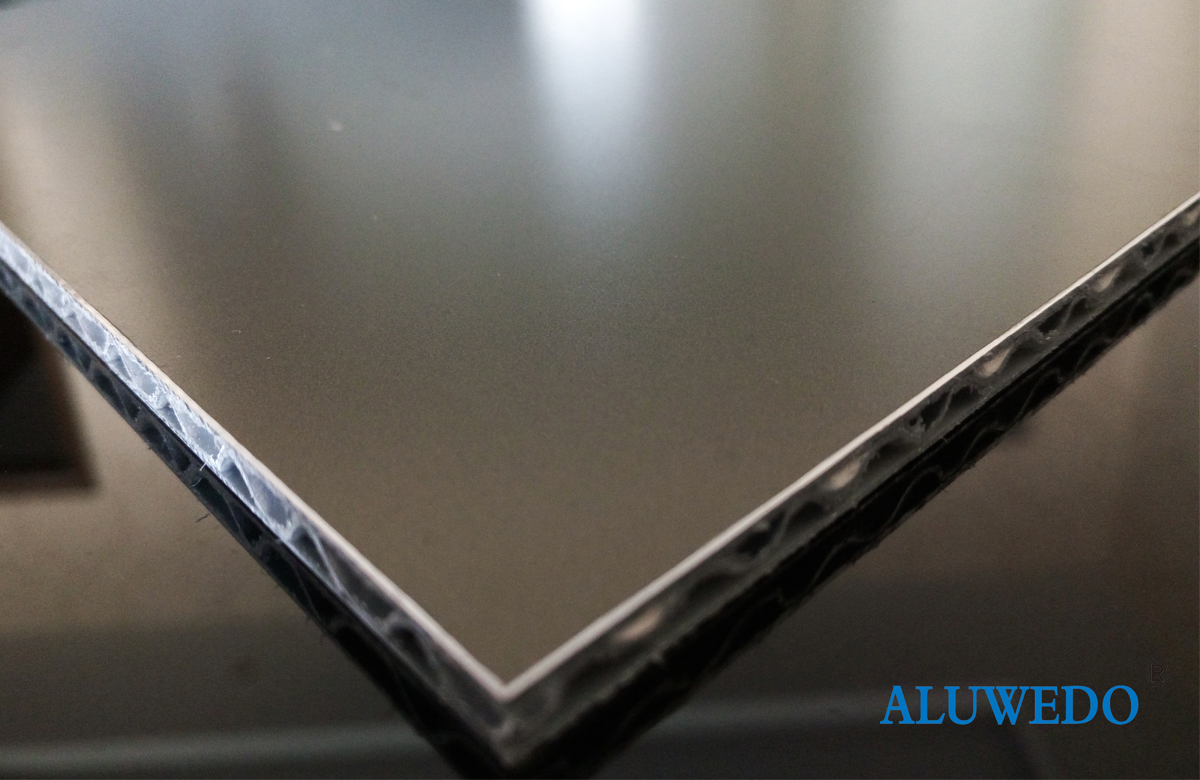

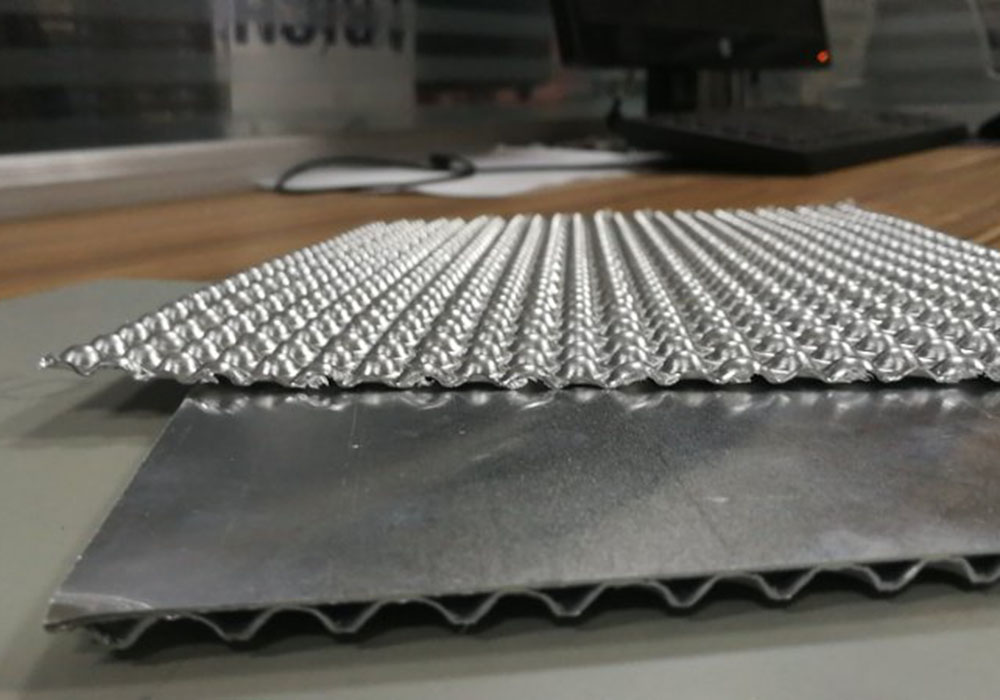

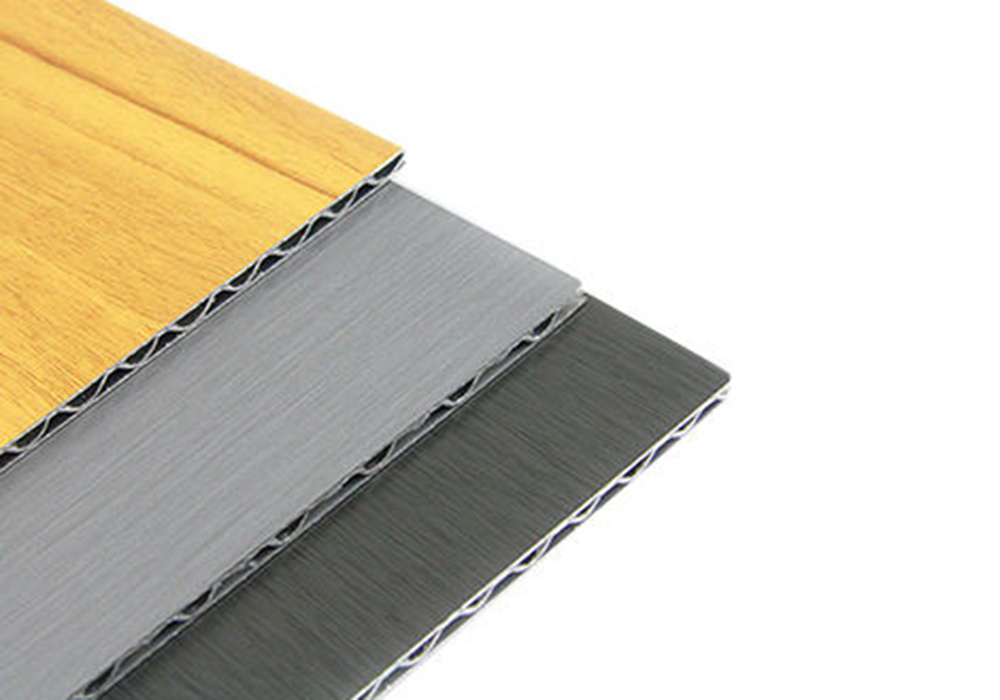

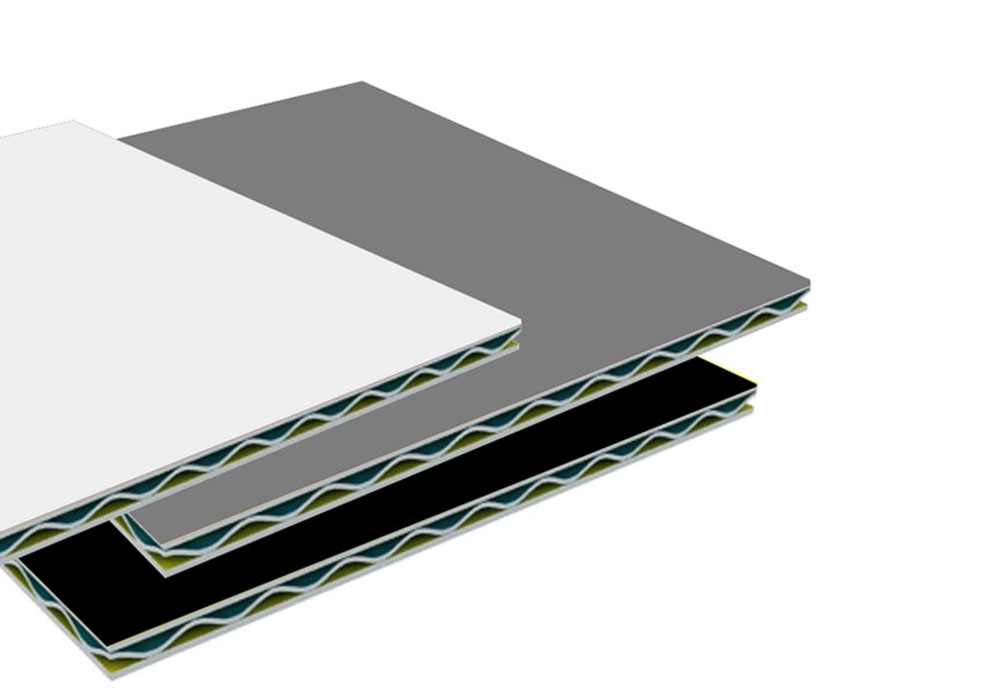

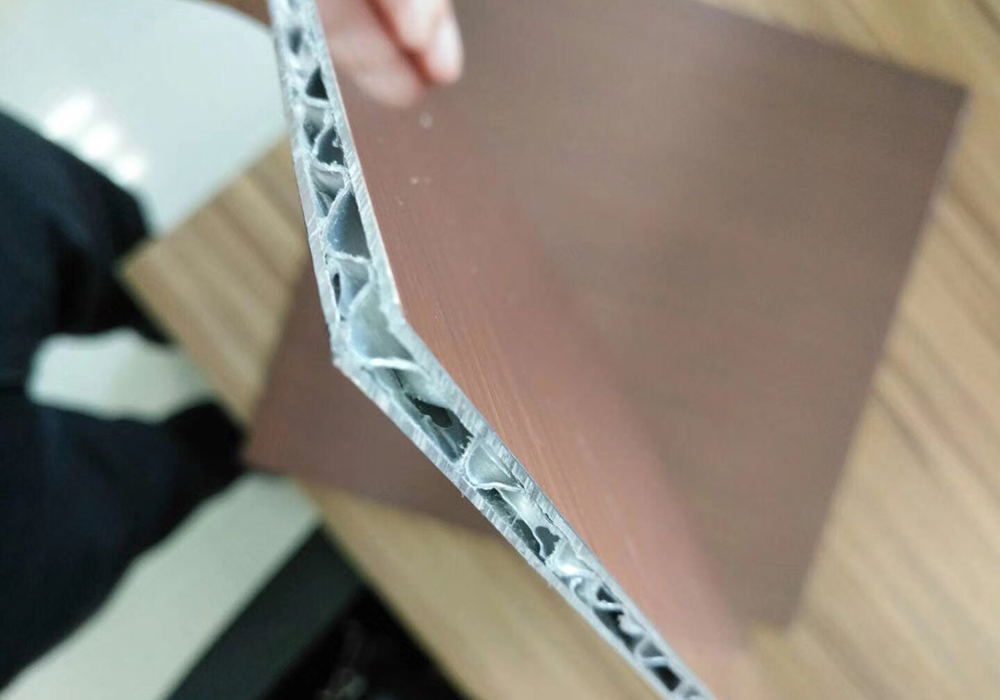

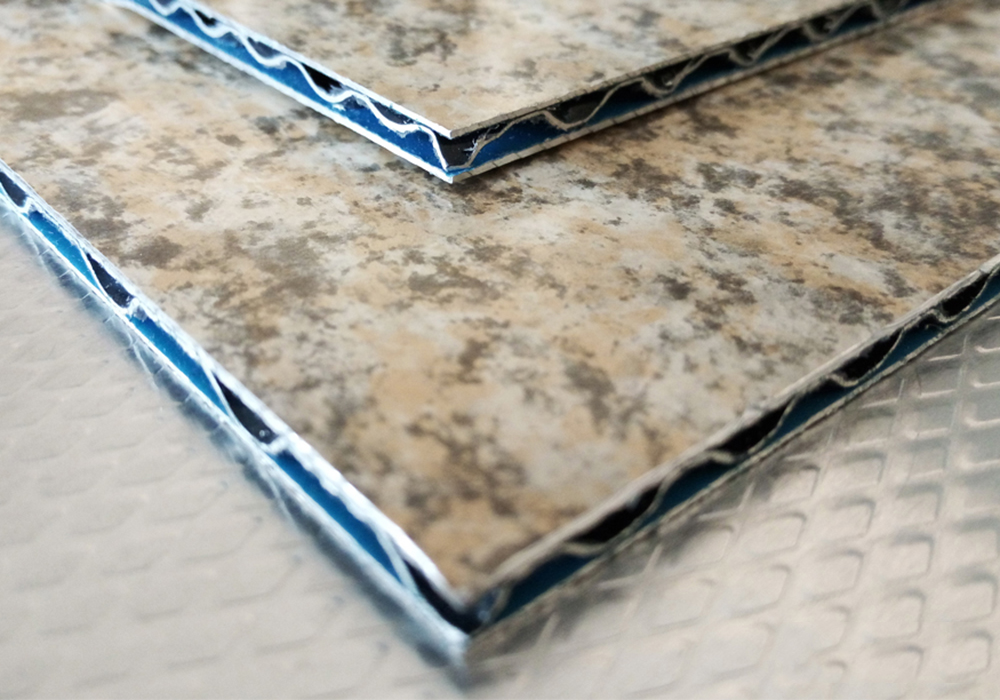

Aluminum corrugated core board, also can be called aluminum three-dimensional board, is an improved honeycomb panel that does not require the expensive unit price of aluminum honeycomb panels, but is stronger and lighter than aluminum honeycomb panels. Its composition is all metal, no plastic components, environmentally friendly and fireproof, but it has the characteristics of aluminum plastic plate omelet processing. The patented three-dimensional physical structure,with the same rigidity, it is much cheaper than the coated solid aluminum plate. The appearance is diversified, whether it is imitation stone, imitation wood or brushed mirror.

With A2 fireproof feature, it a good choice for buildings

-

Strength Panel

-

Connection

-

3D panel

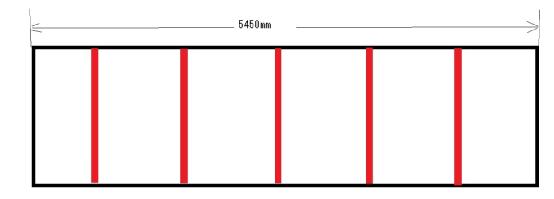

Advice distance for the strength panel is 1m each one

| Panel Thickness | 4mm | 6mm |

| Cover Sheet Thickness | 0.7 | 0.7 |

| Standard Size (W x L ) | 1220 x 2440 mm | 1220 x 2440 mm |

| 1250 x 2500mm | 1250 x 2500mm | |

| 1500 x 3050mm | 1500 x 3050mm | |

| 1500 x 4050mm | 1500 x 4050mm |

The above dimensions are standard ex works.

Individual sizes are available on request.

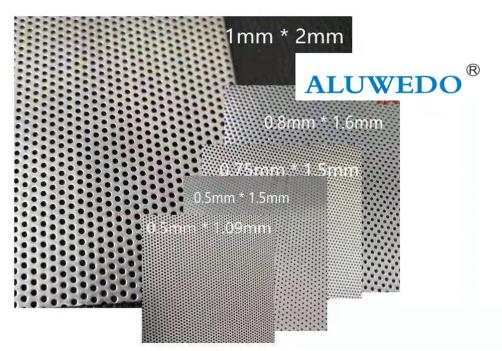

| Aluminum Alloy | 1100 ,3003 ,5005 |

| Paint Supplier | PPG, Becker , Akzo Nobel |

| Core Material | Fireproof A2 Noncombustible inorganic materials |

| Surface Coating | PVDF ,FEVE ,Nano-PVDF ,Spectra-PVDF, Embossed |

The Above materials are regular on request.

Special requirements please contact with Aluwedo Service Team directly.

- Exterior curtain wall

- Building interior wall decoration

- Decorative renovation for old building

- Materials used for vehicle, airplane

- New materials for furniture

> Decorative

The aluminum corrugated composite plate combines the functions and aesthetics perfectly, solving the shortcomings of the aluminum single board and the aluminum sandwich panel, making the appearance more vivid and greatly improving the decorative appearance of the building.

> Excellent Durability

The aluminum corrugated composite sheet has stable and durable bonding properties. Because of the tensile strength and compressive strength, the 180 degree peeling strength is higher than that of the honeycomb panel, so it has ultra-high surface flatness and easy processing, shortening the construction time so that to save cost, the light-weight reduction of the building’s disclosure load can extend the life of the building. It is rich in color, easy to clean and maintain, and has strong corrosion resistance, anti-fouling ability and durability. No harmful gas release, in line with environmental requirements.

> Economic

Light weight, Economical, 6mm thick, specific gravity 4.3kg/m2. Since the heavy load of the face material is small, the structural support keel can be reduced and more economical. The largest specification of the board: large size of 1550mm (width) to 6000mm (longth), improve the utilization rate of materials, and rationally select various curtain walls to improve material utilization and reduce costs.

> Light Weight

The aluminum corrugated composite plate has a weight per unit area of 5kg/m2, which shortens the construction time and is highly effective. The building’s longevity can be extended by reducing the building’s exposure load due to its light weight.

> Processing Ability

Easy to process and install: can be cut, punched, bent, can be made into shaped flat plate or curved plate. The ribs and the reinforcing center can be connected by rivets, which is simple and firm and has architectural art.

> Environmental protection

Aluminum corrugated composite plate is easy to clean and maintain, non-toxic, no harmful gas release, in line with environmental protection requirements.

> Sound absorption

Noise reduction: Since the core plate is corrugated, it produces surface reflection on sound waves and eliminates acoustic coupling between the panel and the back plate, which can improve the sound insulation performance by more than 35dB.

> Insulation

The core of the aluminum corrugated composite plate is water corrugated, forming an air passage between the panel and the back plate, which is the best product for thermal insulation. Under the action of solar radiation, the air in the channel warms up and carries away heat, which has thermal insulation properties. In the cold area, the upper and lower ends of the corrugated channel are sealed. The hot spot rate is minimized due to the characteristics of the closed mechanical structure of the body. Under the sunlight, the stored heat energy reduces the loss of indoor heating heat and has thermal insulation performance

> Fire Resistance

Fire performance: Aluwedo Aluminum Corrugated Composite Plate is made of A3003 aluminum alloy, with good fireproof performance and fire rating A2 non-combustible Aluminum.

-

More details, just feel free to contact us ASAP:

E-Mail: [email protected]

Mobile: +86-13962238789 - Whatsapp: 008613962238789

- Wechat: 008613962238789

-

| Panel Thickness | 4mm | 6mm |

| Cover Sheet Thickness | 0.7 | 0.7 |

| Standard Size (W x L ) | 1220 x 2440 mm | 1220 x 2440 mm |

| 1250 x 2500mm | 1250 x 2500mm | |

| 1500 x 3050mm | 1500 x 3050mm | |

| 1500 x 4050mm | 1500 x 4050mm |

The above dimensions are standard ex works.

Individual sizes are available on request.

| Aluminum Alloy | 1100 ,3003 ,5005 |

| Paint Supplier | PPG, Becker , Akzo Nobel |

| Core Material | Fireproof A2 Noncombustible inorganic materials |

| Surface Coating | PVDF ,FEVE ,Nano-PVDF ,Spectra-PVDF, Embossed |

The Above materials are regular on request.

Special requirements please contact with Aluwedo Service Team directly.

-

-

More details, just feel free to contact us ASAP:

E-Mail: [email protected]

Mobile: +86-13962238789

- Whatsapp: 008613962238789

- Wechat: 008613962238789

-

More details, just feel free to contact us ASAP:

- Exterior curtain wall

- Building interior wall decoration

- Decorative renovation for old building

- Materials used for vehicle, airplane

- New materials for furniture

> Decorative

The aluminum corrugated composite plate combines the functions and aesthetics perfectly, solving the shortcomings of the aluminum single board and the aluminum sandwich panel, making the appearance more vivid and greatly improving the decorative appearance of the building.

> Excellent Durability

The aluminum corrugated composite sheet has stable and durable bonding properties. Because of the tensile strength and compressive strength, the 180 degree peeling strength is higher than that of the honeycomb panel, so it has ultra-high surface flatness and easy processing, shortening the construction time so that to save cost, the light-weight reduction of the building’s disclosure load can extend the life of the building. It is rich in color, easy to clean and maintain, and has strong corrosion resistance, anti-fouling ability and durability. No harmful gas release, in line with environmental requirements.

> Economic

Light weight, Economical, 6mm thick, specific gravity 4.3kg/m2. Since the heavy load of the face material is small, the structural support keel can be reduced and more economical. The largest specification of the board: large size of 1550mm (width) to 6000mm (longth), improve the utilization rate of materials, and rationally select various curtain walls to improve material utilization and reduce costs.

> Light Weight

The aluminum corrugated composite plate has a weight per unit area of 5kg/m2, which shortens the construction time and is highly effective. The building’s longevity can be extended by reducing the building’s exposure load due to its light weight.

> Processing Ability

Easy to process and install: can be cut, punched, bent, can be made into shaped flat plate or curved plate. The ribs and the reinforcing center can be connected by rivets, which is simple and firm and has architectural art.

> Environmental protection

Aluminum corrugated composite plate is easy to clean and maintain, non-toxic, no harmful gas release, in line with environmental protection requirements.

> Sound absorption

Noise reduction: Since the core plate is corrugated, it produces surface reflection on sound waves and eliminates acoustic coupling between the panel and the back plate, which can improve the sound insulation performance by more than 35dB.

> Insulation

The core of the aluminum corrugated composite plate is water corrugated, forming an air passage between the panel and the back plate, which is the best product for thermal insulation. Under the action of solar radiation, the air in the channel warms up and carries away heat, which has thermal insulation properties. In the cold area, the upper and lower ends of the corrugated channel are sealed. The hot spot rate is minimized due to the characteristics of the closed mechanical structure of the body. Under the sunlight, the stored heat energy reduces the loss of indoor heating heat and has thermal insulation performance

> Fire Resistance

Fire performance: Aluwedo Aluminum Corrugated Composite Plate is made of A3003 aluminum alloy, with good fireproof performance and fire rating A2 non-combustible Aluminum.

-

-

More details, just feel free to contact us ASAP:

E-Mail: [email protected]

Mobile: +86-13962238789 - Whatsapp: 008613962238789

- Wechat: 008613962238789

-

More details, just feel free to contact us ASAP:

-